Most companies use industrial oils linearly until the oil deteriorates and is scrapped, and equipment is often lubricated with contaminated oil that can lead to equipment failure. Up to 40%* of maintenance costs are related to lubrication.

How can you improve the cleanliness of your oil and at the same time recycle it to reduce costs?

Today, we’ll show you SKF’s success stories with leading non-ferrous metal producers in China, and the SKF RecondOil® formula that’s way ahead of the curve!

One of the highlights of this project is the “performance contracting” model, whereby the customer is charged according to the achievement of key targets agreed upon by both parties, as opposed to the traditional model of buying and selling products.

This new model allows customers to spend less, more cost-effective, and at the same time, it also properly protects the performance, like insurance! A move to meet the challenges of the customer’s “want, want, want” needs!

The domestic head non-ferrous metal products supplier, whose copper sheet and strip production technology is in the leading position in the industry, needs to use rolling oil with good lubrication performance in the production of copper sheet and strip. Copper strip in the rolling process will produce a large number of pollutants, such as metal particles, moisture, non-metallic particles, etc., these pollutants will affect the cleanliness of the rolling oil, and the cleanliness of the rolling oil will have a direct impact on the service life of the mill bearings and the surface quality of the copper strip.

Copper Plate and Strip

The use of poorly cleaned rolling oil will lead to increased loads on the filtration systems of the production equipment and shorter filter replacement cycles, resulting in higher operating costs for the company and lower product competitiveness. In addition, the company will need to purchase new oil to replenish the loss on the one hand, and at the same time pay a hazardous waste company to dispose of the large amount of waste oil generated from production, increasing the total cost of ownership.

In order to reduce the total cost of ownership and minimise the negative impact on the environment, the head customer wanted to find a way to improve the cleanliness of the rolling oil and at the same time recycle the rolling oil.

It’s SKF’s turn to shine!

SKF RecondOil® System

After understanding the customer’s production needs and pain points, SKF provided a solution in the form of the SKF RecondOil® Max system for bypass purification of the clean tanks of the rolling oil collection and supply system. The system uses the SKF RecondOil® system to clean highly contaminated oil generated during the production process, continuously and deeply purifying the entire rolling oil lubrication system and removing all types of contaminants from the oil.

Ahead of the curve! Domestic SKF RecondOil® Max

SKF RecondOil® system with a capacity of 43 m³/day.

Equipment costs for domestic systems are 63% lower than imports

67% saving in equipment footprint

Modular system design, allowing on-site installation and commissioning

More streamlined and efficient

Lubricant Cleaning Comparison

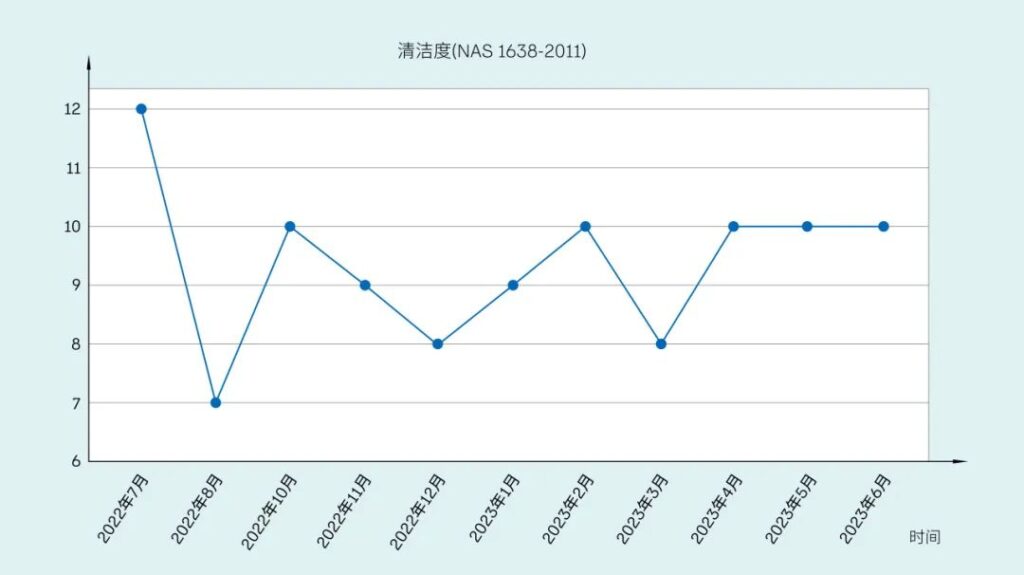

After 11 months of continuous operation of the system, the appearance of the oil in the clean tank improved significantly and the oil became clarified and transparent. The number of particles of different diameters after continuous purification has been reduced very substantially, and the cleanliness is optimised by more than 2 NAS levels, meeting the purification design objectives.

Cleanliness of the net tank oil over time

No problems due to lubrication of the backing bearings have occurred during operation:

Extension of the service life of the filter elements of the original filtration system of the equipment by 8.3 per cent

20% reduction in the amount of rolling oil consumed

Reduction in the number of mill work rolls ground by 10 per cent per month.

SKF RecondOil® solution is not only suitable for metallurgical industry, the same type of copper strip and stainless steel strip rolling oil application, even the oil company also praise its performance, willing to cooperate with SKF to further expand the scope of business.