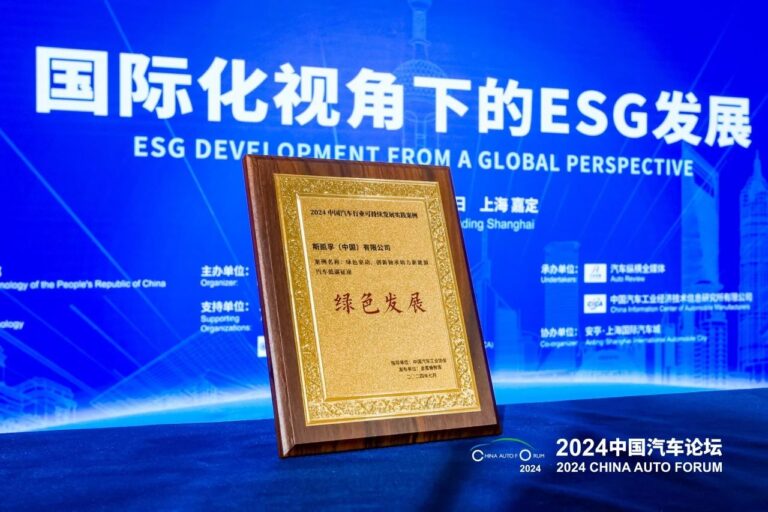

SKF receives the ‘Green Development’ award for outstanding cases of corporate sustainability practices in China’s automotive industry

SKF always takes green and low carbon as the core driving force of development, and contributes to the achievement of global carbon neutrality by continuously optimising product design and production processes to reduce resource consumption and environmental pollution.