At the beginning of the founding of New China, Luoyang was identified as one of the eight key industrial cities in the country, and the First Tractor Manufacturing Plant, Luoyang Mining Machinery Plant, Luoyang Bearing Plant and other “ten major factories and mines” were established in Luoyang, making Luoyang an important industrial base in China.

After the relevant projects were put into production, Luoyang gave birth to the first crawler tractor, the first batch of automobile transmission bearings, the first diesel engine for ships and many other “national firsts”, and “Made in Luoyang” became famous throughout the country.

1959 A “Dongfanghong” crawler tractor, home-made in Luoyang, Henan, testing a wheat harvest

However, under the impact of the market economy and in the face of increasingly fierce competition at home and abroad, outstanding problems such as rigid thinking, institutional constraints and structural imbalance have pushed some of the old state-owned enterprises to the edge of life and death.

Facing the huge pressure of “no reform or death”, Luoyang’s old state-owned enterprises have taken a bold step to carry out reforms, through mergers and acquisitions, stock conversions, staff reductions and efficiency measures, to get rid of heavy burdens, stimulate the vitality of enterprises, and crack the imminent crisis of survival.

At the same time, with the transformation of technological innovation as the support to strengthen the foundation, and the customer first concept as the core to develop the market, the “eldest son of the Republic” enterprise’s golden signboard has been kept fresh and unabated.

\\ Mechanism change, back from the dead

In Luoyang, “innovation and change” is a memory that is engraved in the minds of many old state-owned enterprises after their rebirth.

In 2016, Luoyang LYC Bearing Company Limited (formerly known as Luoyang Bearing Factory), which had been losing money for five consecutive years, started a new round of mechanism change.

In terms of organisation, the management structure and hierarchy were compressed in accordance with the principles of customer focus, flatness, leanness and efficiency; the personnel system adopted a tenure system, a competitive recruitment system, a post salary system and a final elimination system; the salary distribution was tilted towards the three types of front-line positions in R&D, production and sales; and the business segment completed its assessment targets and the staff shared the excess profits.

As Luo Axis was previously bloated with over 20,000 employees at the most, the company’s departments strictly controlled staff increases in order to reduce staff and increase efficiency. “If you want to get a new person in, you have to get rid of one first.” Dong Hanjie, assistant general manager of Luoshaft, said, but for the research and development department, the company fully supports it as long as it is needed for technical research and development, and the R&D centre gives priority to selecting talents among the 100 new undergraduates and above each year.

“The biggest management of the company is personnel and salary management, and the reform has rationalised the distribution system, stabilised the technical team and stimulated staff motivation.” Dong Hanjie said, this is conducive to the decades of technical advantages into production advantages, the brand advantage into market advantages, so that the product is both “good” and “seat”.

After “strengthening the muscles and bones” and “scraping the bones”, Luo Shaft has transformed from 12,000 employees creating less than 2 billion yuan of output value in 2016 to more than 5,000 employees creating more than 5 billion yuan of output value in 2022, with a significant increase in per capita efficiency.

At present, Luo Shaft is aiming to “build a world-class bearing R&D and production base and become an outstanding international bearing supply service provider”, and is striving to achieve a revenue of 10 billion yuan by the end of the 14th Five-Year Plan.

\\ Science and Technology Innovation, Strengthening the Foundation

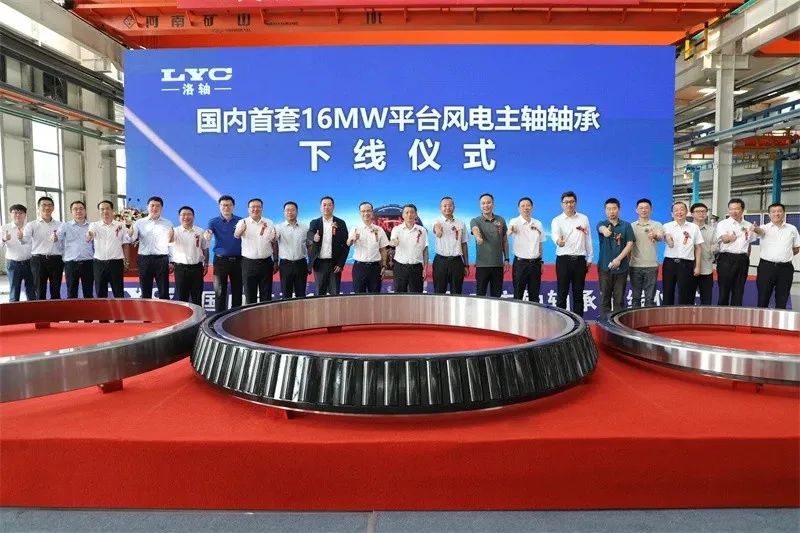

In September 2022, Luo Shaft successfully developed the first set of 16MW platform wind power spindle bearings in China, solving the “neck” problem that has plagued China’s wind power industry for many years, ending the history of China’s inability to develop and manufacture such high-end products, and taking a big step forward in the replacement of key components in the wind turbine industry. “Production generation, reserve generation, research and development generation, in technology research and development, Luo Shaft is never a rainy day.” Dong Hanjie said.

Because of this, over the years, relying on the industry’s only national innovation platform such as the State Key Laboratory of Aerospace Precision Bearings, Luo Shaft has taken the lead in overcoming a series of “neck” technologies in China’s bearing fields such as aerospace, wind power, marine engineering and medical machinery, becoming one of the largest integrated bearing manufacturing enterprises in China’s bearing industry and It has become one of the largest integrated bearing manufacturers in China and continues to maintain a leading position in the industry.

In the industrial base of Luoyang, whether to take the initiative to seek change, or to force reform, Luoyang old state-owned enterprises represented by Luo Shaft in the decades of development, coincidentally will be technical research, scientific and technological innovation as the foundation of the enterprise.

This is also why many old state-owned enterprises, when facing a round of existential crises, were eventually able to turn the crisis into peace by virtue of their strong technological accumulation and superior scientific research strength.

From 2014 to 2016, Sinosteel Luonai suffered continuous losses, was heavily in debt and could not make ends meet. At that time, such “trivial” matters as spending 30,000 yuan to purchase consumables or 13,000 yuan to build a maintenance shed had to be rejected by general manager Bo Jun.

“Money has to be spent where it counts, and not a penny more can be spent where it doesn’t.” Despite this dilemma, in Bojun’s eyes, the money for science and technology innovation must not be saved, “do not rely on science and technology innovation to be productive, the enterprise is weak, other reforms are ‘water without a source’, tossed again, or dead end.

“Technological breakthroughs always go through rough and tumble, and market opportunities always favor those who come prepared. In the eyes of Li Xiongchuan, head of the strategy management section of China YTO Group Co Ltd (formerly known as the First Tractor Manufacturing Plant, or YTO), YTO has twice seized market opportunities by virtue of its technological advantages.

In the 1980s, after the family contract responsibility system was widely implemented in the country’s rural areas, the vast wilderness was divided into small “noodle fields”, the original large horsepower crawler tractor did not adapt to the needs of family production, “the old yellow cow returned to the battlefield, the small donkey high, the tractor left the office The jingle of “the old ox returns to the battlefield, the small donkey is high, the tractor leaves for recuperation” spreads.

At that time, YTO sent personnel to the northeast, northwest, two lakes, two wide and other places back to the farmers’ views, and quickly developed to meet the needs of farmers Dongfanghong 15 horsepower tractor, since then, Dongfanghong “small four-wheeled” in a short period of time will be popular throughout the country, become the standard of many farmers.

In the 1990s, YTO’s performance declined significantly, and in 1994, for the first time since the factory was built, it lost money. During this period, YTO still took on the task of digesting the large wheel tractor technology of Fiat of Italy. Although no return could be seen in the short term, YTO insisted on squeezing out the revenue to support the research and development of large wheel tractors.

Innovation is not easy, but the benefits are not small. 2000 years later, with the gradual expansion of agricultural moderate scale operation, large horsepower wheeled tractors become the main needs of agricultural business entities and agricultural social service organizations, coupled with the country has since launched agricultural subsidies policy, since 2004, tractor manufacturing enterprises ushered in the industry development “golden decade “.

In 2003, after more than 20 years of digestion and absorption of the Italian Fiat large wheel tractor technology, a tractor launched a completely “localized” 80 to 100 horsepower Dongfanghong large wheel tractor series products. The next year, the tractor sold 12,000 units, becoming a sought-after item.

In 2003, a one-off export of 530 tractors to Venezuela became the largest export order for large wheel tractors in China at the time. Since then, China’s export record of large and medium-sized wheel tractors has been constantly refreshed.

“Technology accumulation is not achieved overnight, but the only way to meet the market demand in due time is to continuously carry out technology accumulation.” Li Xiongchuan said that in recent years, in order to adapt to market changes and meet the needs of China’s agricultural modernization construction, YTO has been making breakthroughs in areas such as unmanned intelligent farm machinery technology, new energy tractor technology and hilly mountain tractor technology.

As a science and technology manufacturing enterprise providing mid-to-high-end connectors and solutions, AVIC Optoelectronics Technology Co Ltd (formerly known as Huachuan Electric Factory, or “AVIC Optoelectronics”) has taken the initiative to seek changes over the years and has been developing well, with annual revenue exceeding 10 billion yuan in recent years and growing rapidly, but it still spares no effort in scientific and technological innovation.

AVIC Solar’s new energy international business production workshop

During the “13th Five-Year Plan” period, AVIC Optoelectronics invested a total of RMB 3.481 billion in research and development, accounting for 8.82% of its total operating revenue. In recent years, the intensity of its investment in R&D expenditure exceeds 10%. By the end of 2022, the company had obtained more than 4,400 authorized patents and hosted or participated in the development of more than 850 industry standards.

“Scientific and technological innovation is the foundation of an enterprise, even if the momentum of development of the enterprise is good, technological innovation cannot be relaxed for a moment.” AVIC optoelectronics party construction and publicity department deputy director Wang Weiheng said, it is thanks to decades of insistence on innovation, from electrical connectors to fiber optic connectors, and then fluid connectors, a small mountain village out of the enterprise to develop the electrical, optical, liquid, integrated interconnections and other pillars of the connector industry, to achieve from the “follow” to The “leading” leap.

\\ Customer first, open up the market

CITIC Heavy Industries Machinery Company Limited (formerly known as Luoyang Mining Machinery Factory), a key project settled in Luoyang during the “First Five-Year Plan” period, has faced several crises. 2016 or so, the heavy machinery industry market demand fell, CITIC Heavy Industries’ performance fell off a cliff.

In more than 60 years of development, CITIC Heavy Industries has launched a series of products such as China’s first 2.5m diameter hoist, the largest size and most technologically advanced mill set …… During the period, CITIC Heavy Industries has created nearly 300 domestic and even world “firsts”, “The first,” “leading” record.

But how to turn the technology accumulation into productivity, how to break a new ground when the market of heavy machinery industry is declining, and sometimes torture the “CITIC heavy workers”.

“Mining and major equipment plate as our ‘old family’, play a ‘stabilizer’ ‘ballast’ role. ” CITIC Heavy Industry Party and Government Office Director Ren Hongjun said, but “eggs can not be put into a basket”, to deal with the industry’s shrinking market demand, the only way to enhance the competitiveness of traditional areas, while accelerating the cultivation of new momentum to open up new areas.

Workers cleaning and polishing a batch of exported mining mill cylinders in the workshop of CITIC Heavy Industries

“Selling equipment is a one-shot deal, but doing services is a long-term cooperation.” Ren Hongjun said, from “doing products” to “doing industry” change, is the traditional business growth direction, “like building a water cup, not just satisfied with holding water, but also consider where the water comes from, how to facilitate the problem of boiling water. “

To this end, CITIC Heavy Industries opened a special engineering complete business segment, from providing customers with a single heavy equipment, to provide construction, installation, commissioning, maintenance and other full chain services.

In the cultivation of new dynamic energy, in 2015, CITIC Heavy Industries leveraged the capital market, through investment and mergers and acquisitions, quickly cut into the field of special robotics, high starting point among the first echelon in the field, this segment of business in the mining and major equipment segment when the slump, become an important support point for the company’s profits.

In addition, with the rapid development of the offshore wind power industry, CITIC Heavy Industries had provided key forgings on pile-driving machines for offshore wind power projects, during which it was found that the company not only had the ability to manufacture wind turbine towers and conduit frames, but also the ability to develop and manufacture key components such as pile-driving hammers. “We then broke into a new field through a forging.” In 2020, CITIC Heavy Industries built a production base in Zhangzhou, Fujian Province, and gradually expanded its business from providing components to the whole chain, Ren Hongjun said. Today, the offshore wind power industry is becoming a new growth pole for CITIC Heavy Industries.

In the more than 60 years of development of CITIC Heavy Industries, “customer first” is its business philosophy has always been adhered to. It is no coincidence that in 2019, in the sixteen words of corporate core values selected by the staff of AVIC Optoelectronics, “customer first” ranked first. Wang Weiheng said, “This is an ‘important lesson’ that we learned in the process of climbing over the hump.

“In the 1980s, in the context of the “military-to-civilian” conversion of the defence industry, Huachuan Electrical Factory saw a steep decline in military products, and the factory lost orders overnight. “The only way to cope with the survival crisis was to find new markets.” Wang Weiheng said, looking for orders, run the market is a period of “life-saving” work.

“Our connector products are not shelf products, but customized products, what customers need, we will produce what kind of.” Wang Weiheng said, “customer first” concept is to get out of the crisis in the process of establishing day by day.

In order to mobilise staff motivation, AVIC Optoelectronics took the lead in the 1990s in implementing the reform of the labour and personnel distribution system, establishing an incentive operation mechanism with “market development, technology research and development” staff as the core, so that the income of all employees in the factory is closely linked to the efficiency, according to the work of the pay, more work more reward.

“At that time, there was a controversy about whether the market would feed the factory or the factory would feed the sales, but when the first salesperson received a bonus that was more than the top management, the whole factory was shocked. ‘ to ‘I want to do it’.”

Wang Weiheng said, cadres and staff’s passion for work was fully mobilised, the enterprise marketing and R & D strength continued to strengthen, in 1999, the enterprise loss situation was reversed, in 2000, the enterprise revenue and profit hit the high point of the century.

After emerging from the crisis, the corporate philosophy of “customer first” was not lost, but developed into a unique working model of supporting resources tilted towards the market. “Sales is the biggest ‘customer’ within the company, as long as the sales staff find orders, they have the special right to coordinate the company’s resources to meet the customer’s order needs.” Wang Weiheng said, in the company internal analogy, the next process is the previous process of “customers”, shirk department in the assessment is difficult to pass.

Because of this, AVIC Optoelectronics connector products from the 1970s to the early establishment of the factory of two series, four varieties of development to today’s more than 300 series, more than 250,000 varieties, is accelerating to become the world’s first-class interconnect solutions provider.

For more than 60 years, the golden signboard of the old state-owned enterprise has been kept fresh and unabated on the land of Hailuo.