Brand map|Cone Drive: Leading provider of precision motion control technology solutions

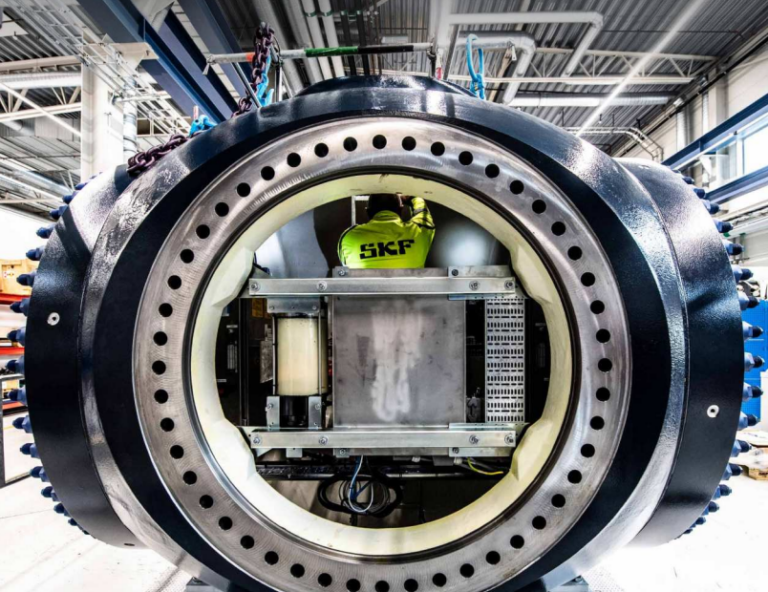

In 2018, Timken acquired Cone Drive. a leading provider of precision motion control technology solutions. The acquisition not only expands Timken's technological capabilities in precision drives, but also strengthens their joint competitiveness in key markets such as renewable energy and automation.