Special heat treatment technology to achieve the industry’s highest level of high load carrying capacity through high temperature dimensional stability, resistance to foreign objects and wear resistance of the two, to achieve miniaturisation and lightweight, and to contribute to energy saving and emission reduction.

(hereinafter referred to as NTN) has developed a new special heat treatment technology, ‘HA-C’, which achieves the industry’s highest level of load carrying capacity, and allows bearings to be further replaced with smaller and lighter products. Specifically, ‘HA-C’ solves the traditional heat treatment, high-temperature dimensional stabilisation and resistance to foreign objects and wear resistance of the difficult dichotomy, the technological breakthrough can contribute to the small size and light weight of electric vehicle drives.

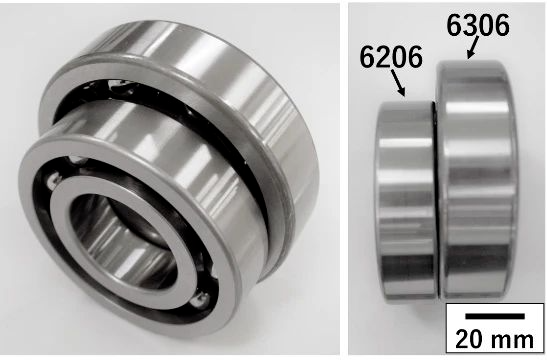

The special heat treatment ‘HA-C’ is used to make bearings smaller and lighter, and deep groove ball bearings 6306 (large) can be replaced with deep groove ball bearings 6206 (small).

Background

In the context of the era of environmental load reduction, EVs and hybrid electric vehicles (HEVs) have been pursuing longer range. To this end, energy conservation is being achieved by reducing the size and speed of the three electric systems and drive units such as reduction gears, and by reducing the viscosity of the lubricant. As a result, ball bearings are required to have both high load and low torque. In addition, in order to solve the problems of heat generation and wear associated with high speeds, bearings are required to reduce dimensional changes over time and wear.

About ‘HA-C’

NTN’s newly developed ‘HA-C’ technology achieves the industry’s highest level of high load capacity by applying special heat treatment to general bearing steel, rather than changing the shape of the bearing. ‘HA-C’ is a method of precise dispersion of fine precipitates of hardness, resulting in very high surface hardness and high load capacity of bearings. Rolling bearings with HA-C technology can cope with harsh environments such as automotive drive systems.

Advantages of HA-C (compared to NTN standard bearings)

*1) Average value calculated by using some of the models in ‘Grease Lubricated High Speed Deep Groove Ball Bearings for EV/HEV (Cat. No. 3040/JE)’.

*2) Based on NTN’s test results under lubrication conditions where oil film formation is difficult.

This technology can be used in our existing high-speed bearings/electrical corrosion-resistant bearings for electric drive systems, solving the technical problem of bearings for new energy vehicle drives. We plan to promote HA-C technology to contribute to further miniaturisation, lightweighting and energy saving of automotive drives.

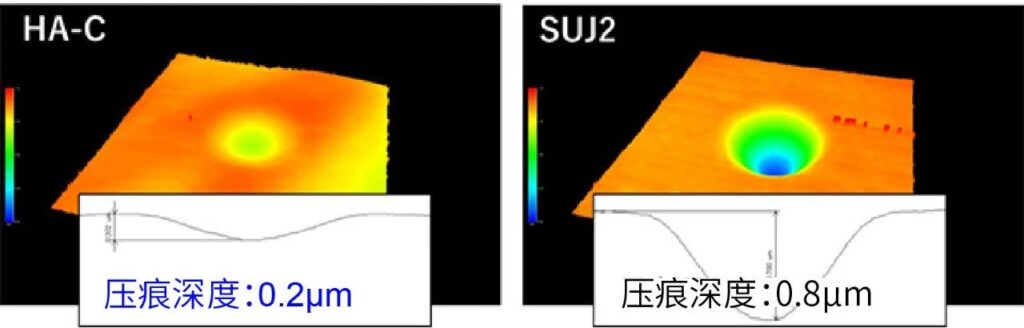

Indentation formation (static load capacity) test results

Indentation shape of 3/8-inch silicon carbide ball (Maximum contact surface pressure: 5.5 GPa)

Left: HA-C applicable product, Right: NTN standard product