Crossed roller bearings are also called cross crossed roller bearings. According to the different rolling bodies, crossed roller bearings can be divided into crossed cylindrical roller bearings and crossed tapered roller bearings.

And tiny crossed roller bearings are a kind of precision mechanical components, which are widely used in micro devices and precision instruments.

Its tiny size and high precision make it an indispensable component in the field of modern technology. In this article, we will have an in-depth discussion on the structure, principle and application of miniature crossed roller bearings in miniature systems.

I. Structure of Miniature Crossed Roller Bearings

1.1 Roller

The core component of a miniature crossed roller bearing is the roller, which is a small but powerful element. The rollers transfer the load on the bearing by rolling between the inner and outer rings, enabling the bearing to withstand large radial and axial loads.

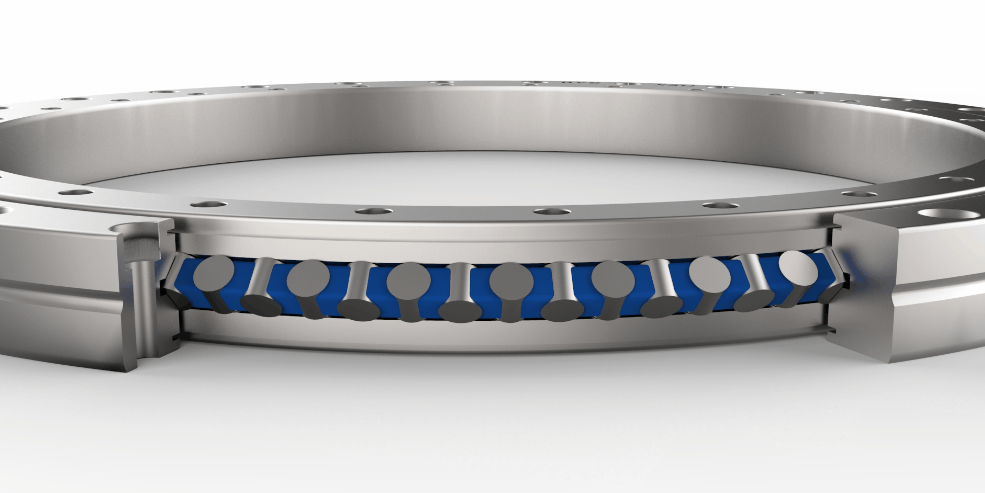

1.2 Inner and outer rings

The inner and outer rings form the exterior frame of the tiny crossed roller bearing and serve to support and locate the rollers. These rings are usually made of high-strength and high-hardness materials to ensure the stability and durability of the bearings.

The working principle of micro crossed roller bearings

The working principle of micro crossed roller bearings is based on the concept of rolling friction. When the bearing is subjected to external loads, the rollers roll between the inner and outer rings instead of sliding, reducing frictional resistance and improving efficiency.

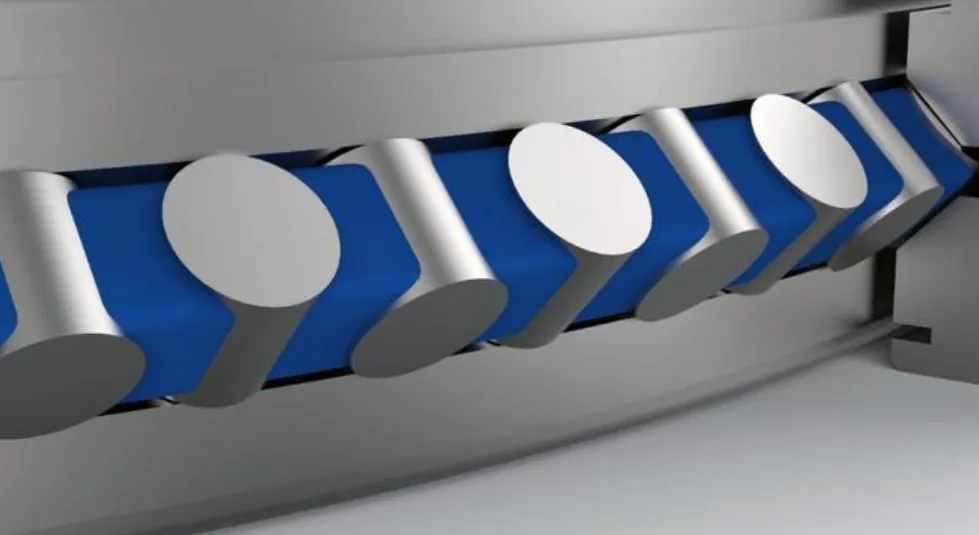

This rolling friction characteristic makes Tiny Crossed Roller Bearings perform well at high speeds and over long periods of time. The internal structure of crossed roller bearings is to use the rollers are 90 ° perpendicular to each other cross arrangement, the rollers are equipped with spacer keeper or isolation block.

These spacer retainers or isolators prevent the rollers from tilting or rubbing against each other, which effectively prevents an increase in rotational torque. This prevents an increase in rotational torque and prevents the rollers from coming into contact with each other or locking up.

Since the inner and outer rings are split, the gap can be adjusted to achieve high precision rotary motion even when preload is applied.

The rollers are arranged perpendicularly to each other on the rolling surface of the V-groove at 90°. This design enables the crossed roller bearings to withstand large radial loads and axial loads.

Application of micro crossed roller bearings

1 Precision instruments

Tiny crossed roller bearings are widely used in precision instruments, such as microscopes, lasers and optical equipment. Their tiny size and high-precision operation enable these instruments to provide high-quality imaging and measurement at the microscopic level.

2 Medical equipment

In the medical field, miniature crossed roller bearings are used in precision medical equipment such as surgical robots and imaging equipment. The high-precision operation of these bearings ensures the accuracy and reliability of the equipment during surgery and diagnosis.

3 Unmanned Aerial Vehicles

The lightweight and efficient nature of micro crossed roller bearings makes them ideal for use in unmanned aerial vehicles such as drones. The high load capacity and low friction characteristics of the bearings are essential for stable flight and long endurance in critical components of the vehicle.

IV. Development trends and challenges

The development trend of micro crossed roller bearings focuses on improving accuracy, reducing size, enhancing load carrying capacity and reducing frictional resistance. With the development of miniaturisation technology and nanotechnology, tiny crossed roller bearings are expected to demonstrate their excellent performance in a wider range of fields in the future.

However, the manufacturing process of high precision requirements, material selection, lubrication and sealing technology and other challenges need to be overcome. Addressing these challenges will drive continuous innovation in miniature crossed roller bearings and provide stronger support for the development of miniature systems.