A wind farm in Henan Province has a high-temperature alarm on the main bearing when the turbine is running, and the customer needs to know quickly the running status of the bearing, whether it needs maintenance, or whether it needs to be shut down to replace a large part.

In the traditional way, it is necessary to take grease samples from the wind turbine, and then send the samples to the laboratory, the customer often needs to wait for 1-2 weeks, during which time either the turbine is shut down resulting in a loss of power generation or the bearings are running sick, causing irreversible damage, which is a situation the customer does not want to see.

SKF has many years of experience in wind power bearing inspection and maintenance, and the customer also has deep co-operation with SKF, then the customer invited SKF to do bearing inspection.

SKF uses grease AI detection technology, after the field maintenance personnel collect grease, the oil sample will be taken to the field station through the microscope scanning, and then upload the photo to the corresponding SKF system website, the same day to get the grease test results, and then based on the results of the grease replacement decision, to avoid long-term downtime due to the bearing alarm, the unit with the disease running situation.

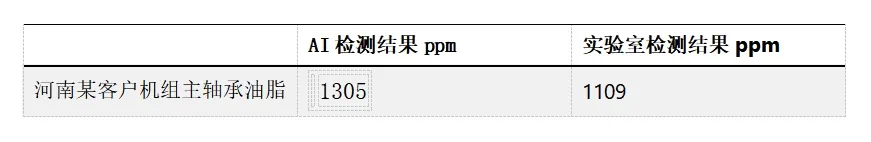

The same batch of grease was also sent to SKF laboratory for comparison, and the detection difference was within a small range.

The customer got the grease results on the same day, and the metal content in the grease had risen. Combined with the offline result comparison, it showed that slight wear had occurred in the bearing, and the customer took the grease replacement to strengthen the bearing lubrication and prolong the service life of the bearing.

SKF can provide professional main bearing inspection and tower maintenance to help customers extend bearing life and reduce life cycle costs.